GENESIS MEMBRANE SEPRATECH P.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to GENESIS MEMBRANE SEPRATECH P.LTD

Micro Filtration Plants (Mf)

62424.jpg)

Microfiltration is a physical separation process. The extent to which turbidity and micro-organisms are removed is determined by the size of the pores in the membranes. When pressure driven fluid flows through a membrane micron sized particles separates from fluid and the process is called Microfiltration. Microfiltration is generally defined to be the filtering of a suspension containing colloids or fine particles in the approximate range of 0.1-10 micron. This size range contains a wide variety of natural and industrial particles such as, silt, viruses, bacteria, clay, colloidal silica, carbon black, paint pigment, yeast cells etc. Micro filtration is a pressure-dependent processes, where large particles get separated from smaller ones along with dissolved solids.

Ultra Filtration Plants (Uf)

62425.jpg)

Ultrafiltration is a membrane process with the ability to separate molecules in solution on the basis of particle size. Ultrafiltration is typically rated by molecular weight cutoff. Ultra filtration can also be applied for pre-treatment of water for nano filtration or Reverse Osmosis. The pores of ultra filtration membranes can remove particles of 0.01 – 0.1 µm from fluids. Ultrafiltration (UF) membranes are able to separate colloids, suspended solids, emulsions, metal hydroxides, bacteria, viruses, emulsified oils, dispersed material and other large molecular weight materials from water and other solutions.

Nano Filtration Plants (Nf)

62426.jpg)

Nano filtration is a technique that has succeeded in the course of recent years which is used most often with low total dissolved solids water such as surface water and fresh groundwater. Divalent and larger ions are generally targeted to be removed by Nanofiltration. Monovalent ions pass through Nanofiltration membrane so it is widely used for desalting application. Removing hardness and dissolved organics from water, arsenic removal from drinking water, heavy metal ions recovery from electroplating wastewater and separation of pharmaceuticals from fermentation broths are some of the examples of industrial applications of nanofiltration. NF has properties that lie between Ultrafiltration (UF) and Reverse Osmosis (RO) with pore size of 0.01-0.001 µm. Since all NF membranes have their origins in reverse osmosis (RO) membranes, they are called loose reverse osmosis membranes or tight ultrafiltration membranes with respect to its permeate flux and separation performance.

Reverse Osmosis Plants (Ro)

62427.jpg)

It is a solute-solvent separation process that uses a dense asymmetric semi-permeable membrane that is highly permeable to water and highly impermeable to solutes. A pressurized feed solution is passed over one surface of the membrane. As long as the applied pressure is greater than the osmotic pressure of the feed solution, “pure” water will flow from the more concentrated solution to the more dilute through membrane. RO membrane is widely used to remove salts from seawater or brackish water. RO membranes can remove solutes in the 0.0001 to 0.1 micron size range.

Membrane Bioreactor (Mbr)

62428.jpg)

Membrane Bioreactor (MBR) systems offer several operational and economic advantages compared to conventional wastewater treatment plants. By incorporating GMS membrane technology, MBR systems eliminate the need for secondary clarifiers and tertiary treatment. This allows for increased performance with a smaller footprint. GMS provides advanced membrane system for any needs. The MBR systems allow for size reduction of the structures required by up to 70 % and even increase the performance of waste water treatment plants along with RO.

Pervaporation

Pervaporation is a process in which a specific component in a liquid feed mixture passes through a dense, non-porous membrane by solution – diffusion transport mechanism. Permeate is collected as vapour on one side while the other side of the membrane is kept under vacuum conditions. Some of the Applications include Dehydration of Organic Solvents. The PV process can easily dehydrate solvent mixtures. The binary or ternary azeotropes can be dehydrated without the use of entrainers. In some cases, where distillation is not possible, pervaporation is the only alternative to costly incineration of waste solvent streams.

Membrane Pilot Plants

GMS offers pilot plant facilities for process development and feasibility studies based on which commercial plants are designed and built. Pilot plant trials are essential to obtain real data for quoting a commercial plant, as well as building confidence and for the customer to become familiar with the technologies. Trials can be conducted at GMS facility or at customers site. This provides an opportunity for the customer to gain first hand experience with membrane operations using their own feed material.

Pre Treatment Systems

Description / Specification of Pre Treatment Systems

We are involved in offering a wide range of Pre Treatment Systems to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pre Treatment Systems. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Post Treatment Systems

GMS provides mixed bed units to suit all of our customers requirements. Cation and Anion resins are combined in a MSRL vessel to produce ultra pure water. Usually a mixed bed unit contains strong acid Cation (SAC) resin and strong base Anion (SBA) resins combined to a ratio of approximately 40% Cation resin to 60% Anion resin. GMS can install mixed bed units after a standard Reverse Osmosis, to produce ultra high quality water. The Cation resins in our mixed bed units are of a higher specific gravity and settle at the bottom of the vessel whilst the Anion resin will automatically float to the top.

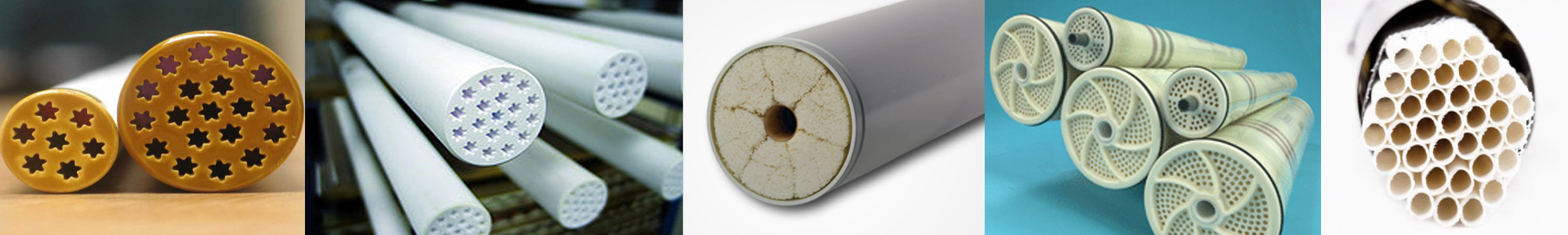

Membrane Modules

Best membrane modules depending upon its geometry, chemistry, inter membrane space are selected for the membrane system for trouble free long lasting performance. GMS provides ceramic membrane for MF in tubular configuration. GMS encourages customers to buy membranes directly from the manufacturers.

High Performance Chemicals

GMS has also solved problems in many big installations in India where the problem faced by the customer was purely due to improper usage of branded chemicals or due to lack of understanding of the problem it self. GMS supplies High performance chemicals for cleaning, scale prevention, bio growth retardation, etc. These are extremely efficient in the control of fouling, removal of scales and flux restoration. These tailor made chemicals have been proven to be superior to generic chemicals, in some cases, besides being compatible with membranes.

Hand Operated Ro

The Hand Operated RO plant has proved to be a boon in areas where water is contaminated with arsenic and/or fluoride which can not be removed by boiling. The operation of the plant is very simple and therefore can be operated by anyone. It does not require any maintenance except for some cleaning and membrane replacement.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

62424.jpg)

62425.jpg)

62426.jpg)

62427.jpg)

62428.jpg)